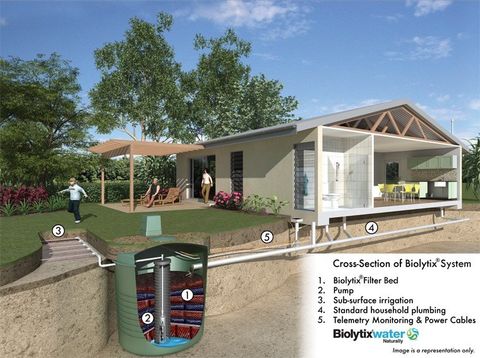

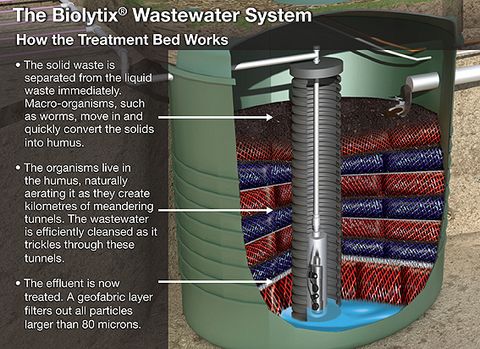

Biolytix BioPod - the natural alternative to septic tanks systems

Nature, not machinery, works hard - so you benefit!

"There are over a million worms in the top humus layer of the BioPod – all waiting for their morning cafe latte." – Dean Cameron, Inventor and Founder of Biolytix.

Why use high-energy mechanical aerators up to 24 hours a day to inject oxygen into wastewater, when the energetic worms and other organisms in the Bio-Pod will continually treat the wastewater using the oxygen from the ambient air in the Bio-Pod? Letting nature do the aeration on a typical on-site wastewater system eliminates more than 1000kW hours per year....equivalent to watching TV 10 hours each day and reduces your carbon footprint by more than 1 tonne of CO2 per year.

An Environment Bay of Plenty Council trial of seven major sewage systems showed Biolytix used by far the least electricity of all of them. The Council report on the Bio-Pod stated:

“One outstanding aspect of this system was its low electricity usage. It used as little as 5% or less of the electricity of some other systems measured.” - On-site Wastewater Treatment System Environmental Discharge Performance Appraisal May 2007. Environmental Bay of Plenty Regional Council.

The BioPod harnesses the energy in the waste (including the sewage, toilet paper and food waste) to nourish the organisms that break down the waste. Nothing is wasted! Contact Davies Plumbing & Drainlaying in Nelson for more details or broucher.

info@www.biolytix.com

Eloy water X-perco c-90New Title

Wastewater arrives into the primary septic tank by gravity from the building. The solid matter will settle on the floor of the primary septic tank to be “degraded” by anaerobic bacteria. The suspended (floating) matter such as fats and oils will form a “crust” at the surface. The outlet of the primary septic tank is fitted

with an approved biological filter to prevent suspended matter from passing through to the second (treatment) compartment.

Xylit Trickling filter

The pre-treated and filtered waste enters the Xylit filter bed by gravity into the distribution device “tipping trough”. The tipping trough fills and alternately disposes into a network of perforated pipes (spider) to evenly distribute influent over the Xylit filter bed.

The “pre-treated” waste water slowly trickles through the Xylit media, where the population of digesting bacteria develop to digest and purify the waste liquid.

Oxygen is supplied to the filter by a network of 100mm diameter pipes. This is achieved with No power.

Distribution

The treated water leaves the filter by gravity from the floor of the filter tank into the dose flout (no power) or pump chamber 6. The treated water is gravity dosed or pumped into the land application (disposal) area

The land application area is chosen for its potential for gravity or pumped distribution. The treated waste can be distributed through drip irrigation, LDPE or UPVC piped trenches.

The X-perco has a small battery operated alarm that will activate in the unlikely event the water level.

info@eloywater.co.nz

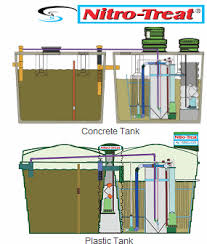

Waipapa Tanks and wastewater treatment systems

Davies Plumbing & Drainlaying uses Waipapa Tanks systems throughout the Nelson and Tasman area.

With over 20 years experience Waipapa Tanks is proud to have built an excellent reputation for their complete package of design, manufacture, installation and maintenance of their wastewater treatment systems and tanks.

Waipapa Tanks provides environmentally friendly wastewater treatment systems for domestic or commercial in plastic or concrete. Waipapa Tanks design, manufacture, sell and install aerated sewage treatment systems that have certification from the National Test Field in Rotorua.

www.waipapatanks.co.nz

Wastewater Engineering services

Mark Rounce

Bachelor Of Engineering Civil (Hons)

Diploma Of Project Management

New Zealand Certificate in Engineering Civil

Services provided

- Domestic Wastewater Design and Reporting for Resourse Consent and Building Consent Applications

- Domestic Wastewater Design and Reporting for Certificate of Acceptance

- Commercial Wastewater Design

- Subdivision Wastewater Feasibility Reports

- Wastewater Expert Witness

- Stormwater Soakpit Design and Reporting for Resource Consent and Building Consent Application New Title

Contact details:

PHONE

(03) 545 1758

0274 768002

Email

mark@rounce.co.nz